TRICOFLEX SUSTAINABLE RANGE

TRICOFLEX

TRICOFLEX SUSTAINABLE RANGE

TRICOFLEX: Introducing an eco-friendly range dedicated to sustainability. TRICOFLEX, a pioneering French company in the manufacturing of flexible PVC hoses TRICOFLEX, established in the 1950s in France, excels in developing and producing flexible thermoplastic hoses and became part of the EXEL Industries group since 2012. With a reputation for quality spanning over 65 years, the company places high importance on customer satisfaction, eco-friendliness, technical proficiency, and innovation. It serves a global clientele in various industries—ranging from agriculture to firefighting—via an extensive distribution network, offering over 1000 stock items. Moreover, its commitment to sustainability includes sorting, recycling, and processing over 2,500 tons of PVC waste each year. TRICOFLEX, an eco-responsible partner TRICOFLEX is dedicated to employing a circular economy model, which focuses on maximizing resource efficiency and minimizing carbon emissions by incorporating recycled materials.

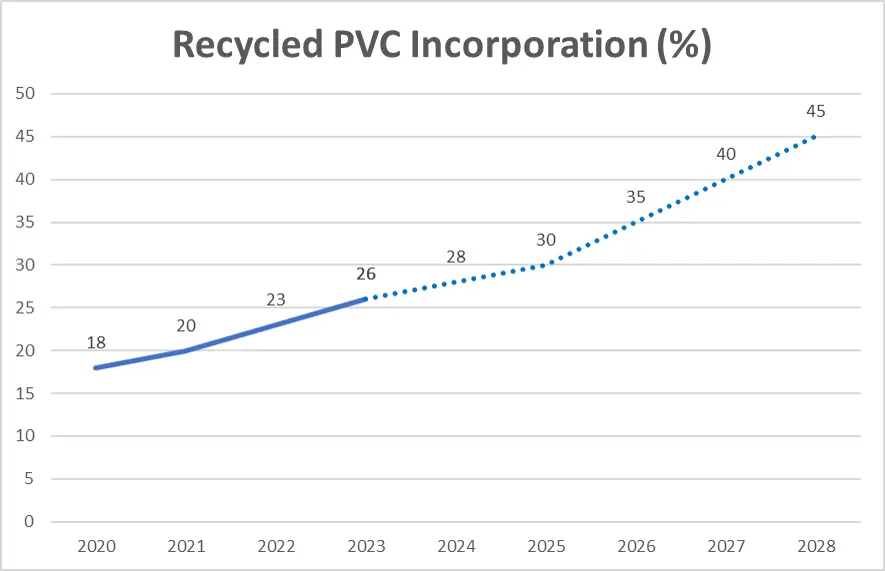

The company repurposes its production scraps by reintroducing them back into its production cycle. Additionally, it sources recycled PVC from outside providers. By producing select hose ranges with a composition of up to 70% recycled content, TRICOFLEX significantly cuts down on virgin raw material usage, waste production, and, as a result, its overall environmental impact. In 2020, the company incorporated 18% recycled PVC on average in its hoses and aims to increase it to 45% by 2028. Consequently, it will cut its per-unit greenhouse gas emissions by 30% by this time.

The sustainability initiatives have earned the following acknowledgments:

- The European MORE label, established by the Federation of Plastics and Composites, honours manufacturers that incorporate recycled plastics into their manufacturing processes, thereby cutting down on greenhouse gas emissions.

- The EcoVadis medal, an internationally acknowledged award, evaluates the sustainability activities of companies.

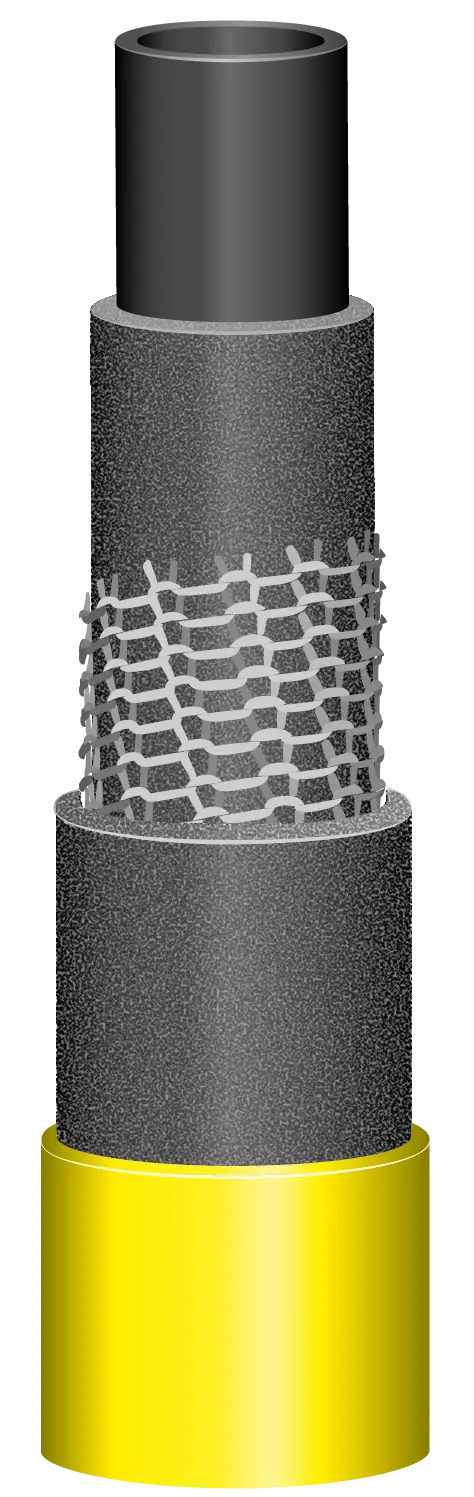

Currently, TRICOFLEX is advancing its commitment to environmental responsibility by introducing a new line of hoses composed of a minimum of 90% recycled material. Introducing a sustainable, high-quality product line from the TRICOFLEX brand TRICOFLEX is committed not only to recycling but also to innovation. The company is developing a novel series of water hoses composed of at least 90% recycled materials, delivering the same quality and efficiency as their conventional counterparts. These innovative hoses feature knitted reinforcement (i.e. TRICOFLEX's non-torsion technology TNT), allowing high flexibility and resistance to twisting under pressure. These hoses are versatile and can be used in various applications including irrigation, cleaning, or on construction sites. These hoses will be presented in eco-friendly packaging, featuring a light, FSC-certified label that ensures responsible forest management, and will eliminate the need for separate wrapping for each coil.

TRICOFLEX's latest sustainable hose series advances its commitment to minimising environmental impact. Having introduced products like the Irriflex and Primabel, Reco hose, and international range hoses made from 70% recycled PVC since 2022, TRICOFLEX now progresses with its 90% recycled material hoses, balancing eco-friendliness with efficiency. The main obstacle of this project is to enhance the quality of recycled plastics to use them in every layer of the hose. It demands a cross-functional team effort, considering resource accessibility, refining recycled material quality by reformulation, and tweaking processing settings for manufacturing hoses with a significant amount of recycled plastic. These hoses with enhanced sustainability will be accessible to customers in 2025, offering a greener solution for water transport to consumers.

Conclusion

TRICOFLEX is dedicated to environmental sustainability, providing customers with durable, eco-friendly products. Its recent collection of hoses made from 90% recycled material showcases the feasibility of combining sustainability with functionality. The hoses await certification on Recycled Plastic Material (RPM), provided by the LNE (Laboratoire National de Métrologie et d’Essais), an external institute that audits and verifies compliance with strict standards to ensure the accuracy of their plastic composition

Warum ist das Projekt einzigartig?

- Sustainable water hose containing a minimum of 90% of recycled plastics

- Improved carbon footprint

- High performance and durability, similar to hoses made of virgin plastics 4) Eco-friendly packaging 5) % of recycled material certified by an external institute (LNE)

Zielsetzung

Tricoflex aims the development of a new range of water hose, composed of at least 90% recycled plastic materials and delivering the same quality and efficiency as their conventional counterparts made of virgin plastic materials.